| April 7, 2025

During the Hannover Messe 2025, we presented the BUA Mobile Lab, and both the Open.Make and the LAUDS Factories projects. We got the chance to talk with experienced experts from industry including engineers, managers, consultants and business leaders about hardware development practices. Key topics included how they are currently documenting their projects and how open collaboration can be a valuable tool for driving innovative open source hardware development. The most valuable outcome for us was to realize that our academic research is of relevance to the industry and could find application there as a means for open innovation projects and research transfer. We were also invited to join the GITEX Europe fair in Berlin from the 21st to the 23d of May.

We will report our take home message from both fair in a blog post series. In this first episode, we will present our personal experiences at the Hannover Messe fair, while following episode will (probaly, stay tuned) talk about “Open innovation = together”, “prototype review and quality check”, the “role of makerspaces”, and “Open Source Hardware for the industry”.

Five people, five days at the Hannover Messe

The Hannover Messe sets an ambitious five-day exhibition presence. The world of an industry fair is entirely different from an academic conference, as most people are there to build business connections or to introduce, sell and buy products. We were in the Hall 2: Future Hub dedicated to future technologies and industrial research, which had its own exciting flair of deep technology, applied research for industrial transformation, research transfer, startup culture and international networking. Each evening between the exhibition days had its own party with live music and free food and beverages for exhibitors. As Canada was the host country, they came with a large delegation and a lot of well-curated booths in various halls. Also, the party they organised was a pretty large concert and DJ performance by dynamic young Canadian artists, which represented well the fresh breeze by the Canadian corporate delegation.

We went there with our BUA Mobile Lab to present our work on open source hardware (OSH) and open and sustainable manufacturing inside both the Open.Make and the LAUDS Factories project. While our presented research activities are geared towards manufacturing with digital machines as used in fab labs and makerspaces, both projects share a special focus; the potential and challenges for developing, transferring and producing open source hardware for new alternative research transfer and market opportunities as well as societal benefits.

We were five at the Messe: the three main researchers of the Open.Make project (Dr. Mies, Dr. Colomb, Mr Maxeiner), one TUB student, and Mr Klein from Mekanika SRL, a Brussels-based company, which is one of our partner in the LAUDS Factories project. Mr. Krüger, another TU colleague came on Friday. Our stands was presented on the messe webpage.

We had a small booth at the main space organised by the TUBS GmbH for the Berlin and Brandenburg region on top of our Mobile Lab setup. On the TU space, we presented our design review and publication tool.

In addition, our “low-tech” demonstrator, the “smoothieclette” was also set there ( a treadmill used to make smoothies). We used the Low-tech fanzine and book from the LT4sustain project to discuss the concept with the visitor. Later on, we also added a laser engraved QR code (created using the R package qr_code, as demonstrated below) linking to the documentation of the project.

qrsmoothieclette = qrcode::qr_code("https://codeberg.org/openmakeXlowtech/PedalPoweredMachine-4fablab")

plot(qrsmoothieclette)

Ten meters away, we parked our BUA Mobile Lab, which is equipped with a 3D printer (Prusa MK4S), a laser cutter, a CNC milling machine (Mekanika Mk2 PRO), and a set of manual tools. This setup is designated as a mobile, entry-level makerspace offering for open source hardware development by students and researchers at the Berlin universities, and we had completed it just in time for the Hannover Messe. During the Messe we produced a few acrylic information plaques (like the one for the smoothiclette described above). We also manufactured a staircase using the CNC milling machine during the Messe. The staircase allows for more people to enter the BUA Mobile Lab, and was a lot of fun to create (both designing and producing it was a learning experience). Om the back, we also installed the Mekanika screen printing press and printed some bags.

The Mobile Lab doors were decorated with two mini poster presenting the Open.Make and the LAUDS Factories concepts: On the left door, a poster about transforming makerspaces from prototyping and teaching spaces, into production facilities; on the right a poster on open source hardware: opening up the product, opening up the process, and why this is desirable: achieve better and more sustainable products.

We were also showcasing our hardware documentation guide, the OPENNEXT handbook (https://berlinup.books.tu-berlin.de/produkt/978-3-98781-013-8/),,){.uri} and the OPENNEXT project video explaining the basics of open source hardware development and the need for physical manifestation in makerspaces (https://www.youtube.com/watch?v=tWyUDsQLEVc)..){.uri}

This was enabled by the presence of Mr Klein from Mekanika, who joined us from Tuesday to Thursday. Mekanika enriched the BUA Mobile Lab booth as co-exhibitor showcasing their open source CNC milling machine technology. Their capabilities came in handy for us not just as open source technology provider, but as part of a train-the-trainer approach as important component for creating viable offerings for supporting prototyping within open source hardware projects.

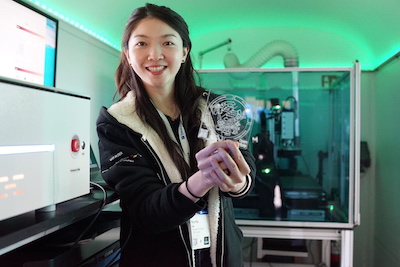

Chia Yin Lin (TU Berlin student and research assistant) was also there for the whole week, notably designing and graving plaques and presenting our work to international visitors, in several instances even in Mandarin. Our new colleague Sebastian Krüger joined us on Friday, notably assisting with the final stages of the staircase creation and helped us to secure the machines for transport at the end of the day.

As highlights during the week, we had the honor and pleaseur to have a planned visit from Dr. Severin Fischer, the state secretary of Berlin, on Monday. On Wednesday, we had important discussions with the person representing the transfer office of the TU Berlin at the fair on the use of our documentation review system. On Thursday, we got invited to the GITEX Europe 2025 fair in Berlin, which demonstrate our presence was well prepared and received and we gave a talk on the technology transfer stage. On Friday, we finished the production of our staircase. In general though, we spend most of our time talking to people, both presenting our work and collecting data on questions defined before the fair. We also drank a lot of coffee to keep us going… All this was scheduled and organised by the ABSOLUTELY GREAT TUBS GmbH team (thanks again to all of you!). There was also a very nice and warm interaction with fellow exhibitors from Berlin Brandenburg as well as all the neighbouring stands in hall 2.

We return from Hannover with a lot of new contacts (TU tranfer office and other potential research and teaching partners for our courses and future grant application) and the impression that what we do is actually useful to the industry, something engineers but not biologist would expect. Understanding how collaborative work for hardware development can be organised is a valuable input, not only for researchers but also for the industry, which happens to face very similar problems. We apparently provide solutions to problems that older engineers have been dealing with for years in their work. It seems that these problems need to be explicitly dealt with, as part of collective efforts. Many visitors also expressed the importance of our work for wider society, especially its putative importance in facing the environmental crises, collectively.

.jpeg)